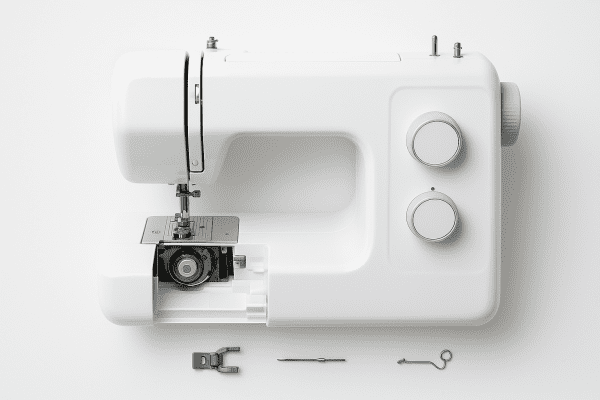

A mechanical sewing machine remains a trusted choice for beginners and seasoned sewists alike, thanks to its simplicity, reliability, and straightforward controls. Whether you’re outfitting your home sewing room or looking for a dependable craft sewing machine, understanding the mechanics of sewing machines can help you find the perfect fit for your projects. In this comprehensive guide, we’ll explore everything from essential sewing accessories and maintenance tips to comparisons with computerized models and expert buying advice—ensuring you get the most from leading brands like Janome and Singer.

Featured Products

Best Overall • Best Value • Premium Option

Note: As an Amazon Associate I earn from qualifying purchases. Some of the links on this site are affiliate links — when you buy through those links, I may earn a small commission at no extra cost to you.

Understanding Sewing Machine Mechanics and Stitch Technology

A mechanical sewing machine uses gears, levers, and dials to create stitches. These sewing devices rely on manual adjustment for each function. Mechanical machines are popular in home sewing and crafts sewing machine projects due to their reliability and ease of use.

Each sewing apparatus operates with a set of core parts, including a bobbin, needle, and feed dogs. Users control stitch length and type using simple mechanical controls. Understanding the basics helps with both sewing projects and maintenance. Next is a look at the core mechanical functions and stitch types overview.

Core mechanical functions and stitch types overview

- Mechanical sewing devices use manual dials to adjust stitch length and width for different sewing projects.

- Feed dogs work with the needle to move fabrics smoothly under the sewing apparatus during operation.

- Stitch types on a mechanical sewing machine typically include basic straight, zigzag, and buttonhole options for garment or textile machine work.

- Regular maintenance of sewing equipment, such as oiling and cleaning, keeps the mechanics of sewing machines running smoothly for home sewing arts.

Key Sewing Machine Parts and Bobbin Functionality

Every mechanical sewing machine relies on key sewing accessories and moving parts. The bobbin is a core piece of sewing technology, holding the lower thread for each stitch. Understanding these sewing machine components helps users get consistent results and keep their sewing device running smoothly.

The bobbin system works with the needle and feed dogs to form strong stitches. Regular cleaning and oiling of sewing equipment prevents jams and wear. Knowing how each mechanical sewing gadget functions is essential before exploring the essential components and bobbin system breakdown.

Essential components and bobbin system breakdown

- The presser foot holds fabric steady while the feed dogs advance material through the sewing machine.

- A front-loading or top drop-in bobbin system supplies lower thread for consistent stitching on any textile machine.

- Manual dials on mechanical sewing machines adjust tension and stitch width for various sewing projects and fabrics.

- Needle plate markings help guide seam allowance and improve accuracy in garment construction with any home sewing machine.

Selecting Sewing Accessories for Mechanical Sewing Devices

Choosing the right sewing accessories is essential for any mechanical sewing machine. The right sewing tools support smooth sewing projects and protect your sewing device. Quality sewing accessories also help maintain the performance of your sewing equipment and extend its life.

Accessories like extra bobbins, universal presser feet, and sharp needles improve your sewing experience. Many craft sewing machine owners also use seam rippers and fabric scissors for better results. Prices for basic sewing supply kits typically range from $15–$30 per set. Next, explore must-have accessories for mechanical sewing machines.

Must-have accessories for mechanical sewing machines

- A sturdy seam guide keeps fabric sewing machine stitches straight for garment construction.

- Assorted machine needles allow your sewing device to handle different fabrics and sewing projects.

- Extra bobbins ensure your mechanical sewing machine is ready for quick thread changes during sewing arts.

- A quality presser foot set expands sewing tools for more advanced mechanical stitch machine techniques.

Essential Maintenance for Sewing Machine Durability and Performance

Regular maintenance keeps your mechanical sewing machine running smoothly. Cleaning and oiling your sewing device helps prevent costly repairs. Proper care extends the life of sewing equipment and protects your investment in any home sewing machine or craft sewing machine.

Dust, lint, and thread can cause issues inside your sewing apparatus. Use sewing tools like a small brush and sewing machine oil for upkeep. Maintenance supplies typically cost $8–$18 per kit. Next, learn about routine care tasks for optimal machine health.

Routine care tasks for optimal machine health

- Replace sewing machine needles regularly to protect your sewing device and ensure smooth fabric handling.

- Remove lint from the bobbin area and feed dogs after each sewing project to prevent issues in your mechanical sewing machine.

- Check and tighten screws on your sewing equipment to keep the mechanics of sewing machines properly aligned.

- Inspect the presser foot and needle plate for damage to maintain performance on any home sewing machine or mechanical textile machine.

Troubleshooting Sewing Machine Tension and Feed Dogs

Mechanical sewing machine tension issues and feed dog problems often affect stitch quality. Proper settings are critical for any home sewing machine or craft sewing machine. Understanding these sewing mechanics helps prevent skipped stitches and fabric jams during sewing projects.

Thread bunching or uneven fabric movement can signal a tension or feed dog issue in your sewing device. Adjusting dials and regular cleaning often fix these mechanical sewing gadgets. For simple fixes, review the common tension and feed dog adjustment tips in the next section.

Common tension and feed dog adjustment tips

- Adjust the tension dial gradually on your mechanical sewing machine to achieve balanced stitches across different fabrics.

- Raise or lower the feed dogs using the lever on your sewing device when switching between quilting and standard sewing projects.

- Clean the feed dog area on your craft sewing machine regularly to prevent thread buildup that can affect stitch quality.

- Test settings on fabric scraps before starting garment construction to ensure your home sewing machine delivers even feed and proper stitch formation.

Ensuring Sewing Machine Safety and Electrical Compliance

Safe operation is vital for every mechanical sewing machine. Proper electrical compliance protects your sewing device and home. Users should check their sewing equipment for correct voltage, secure cords, and functioning safety features before each project.

Always unplug your sewing machine mechanical before maintenance. Inspect the sewing apparatus for frayed cords or exposed wires. Follow electrical standards for all home sewing machine models. These steps help avoid accidents and equipment damage. Next, review Safety checks and compliance considerations for users.

Safety checks and compliance considerations for users

- Confirm your mechanical sewing machine complies with local electrical standards before using in a new region.

- Inspect sewing machine accessories, such as power cords and foot pedals, for wear to prevent hazards.

- Store your fabric sewing machine and sewing tools in a dry area to avoid electrical issues and rust.

- Use only recommended replacement parts for sewing equipment to maintain safety and performance compliance.

Enhancing Sewing Projects with Specialized Sewing Tools

Specialized sewing tools help every mechanical sewing machine perform better. These sewing accessories make sewing projects easier and more precise. Using the right sewing tools can improve results for both craft sewing machine users and home sewing machine owners.

Tools like seam guides, thread cutters, and needle threaders help with accuracy. Presser feet kits and fabric clips are useful for many sewing projects. Prices for these sewing supply accessories typically start at $10–$25 per set. Next, see which Specialized tools to improve sewing machine results can boost your sewing experience.

Specialized tools to improve sewing machine results

- Quilting guides attach to your mechanical sewing machine for precise parallel lines on fabric sewing projects.

- Bias tape makers help craft sewing machine users create custom trims for garment construction and home sewing arts.

- Walking feet ensure even feeding of multiple fabric layers on a mechanical textile machine or industrial sewing machine.

- Magnetic seam guides improve accuracy on sewing equipment and support consistent seam allowances for sewing mechanics.

Comparing Mechanical Sewing Equipment for Home and Textile Use

Mechanical sewing machines come in both home and textile machine types. Home sewing equipment is designed for everyday sewing projects and garment construction. Textile machines, often called industrial sewing machines, handle heavier fabrics and higher volumes. Both types rely on manual controls for core sewing functions.

Home mechanical sewing devices are smaller and easier to move. Industrial sewing machines are larger, more powerful, and built for long hours. Prices for home sewing machines typically range from $120–$420 per unit. Next, explore the key differences between home and textile machines for better decision-making.

Key differences between home and textile machines

- Industrial sewing machines offer higher sewing speed and continuous operation for large-scale textile machine production.

- Home sewing equipment is designed for versatility and accommodates a wider range of sewing projects and fabrics.

- Mechanical textile machines use heavier-duty mechanics and components for sewing apparel and upholstery.

- Craft sewing machine models for home use prioritize ease of use and compact size over the power of an industrial sewing machine.

Organizing Sewing Machine Storage and Accessory Solutions

Keeping your mechanical sewing machine and sewing accessories organized protects your investment. Proper storage extends the life of your sewing device. It also makes sewing projects smoother. Organized sewing equipment helps you find sewing tools fast and prevents lost or damaged sewing supply items.

Use storage carts, clear bins, and drawer organizers for sewing gear. Many fabric sewing machine owners prefer stackable boxes for sewing machine accessories. Wall-mounted racks keep sewing tools visible and tidy. Prices for storage solutions typically start at $15–$50 per unit. Next, explore Storage ideas for machines and sewing supplies for every workspace.

Storage ideas for machines and sewing supplies

- Use a padded carrying case to protect your mechanical sewing machine during storage or travel.

- Install pegboards to hang sewing tools and keep sewing accessories visible in your workspace.

- Dedicate a drawer for bobbins, presser feet, and needles to organize small sewing supply items.

- Label bins for fabric sewing machine parts and sewing equipment to streamline project setup.

Maximizing Warranty and Support for Sewing Machine Longevity

Protecting your mechanical sewing machine starts with understanding warranty and support. Good warranty coverage extends the life of any home sewing machine. Reliable support helps fix sewing equipment issues quickly and keeps your sewing projects on track.

Most mechanical machines include a frame warranty and limited coverage for sewing accessories or electronics. Support options often include phone, email, or local repair centers. Costs for out-of-pocket repairs typically range from $70–$120 per service. Next, review Warranty coverage details and support best practices.

Warranty coverage details and support best practices

- Register your mechanical sewing machine promptly to activate sewing equipment warranty and receive service updates.

- Keep records of sewing machine repairs and maintenance for warranty claims on your textile machine or home sewing machine.

- Use authorized service centers for support to protect sewing device eligibility under manufacturer policies.

- Consult your sewing supply documentation for coverage limits on sewing accessories and machine mechanical parts.

Final Thoughts:

A mechanical sewing machine remains a dependable choice for anyone seeking simplicity, durability, and hands-on control in their sewing projects. Whether you’re working on home sewing machine tasks or tackling crafts sewing machine creations, this type of sewing equipment offers reliability and ease of use. Leading brands like Janome continue to innovate while honoring tradition. If you value straightforward mechanics and long-term performance, consider exploring different sewing machine models to find the best fit for your needs—start your next sewing project with confidence today!

Frequently Asked Questions (FAQs)

What are the main advantages of using a mechanical sewing machine over a computerized model?1

Answer: A mechanical sewing machine is simple, reliable, and easy to repair. This sewing device handles home sewing projects and garment construction well. The sewing equipment uses fewer electronics, so maintenance is easier. Mechanical machines last longer. Many users prefer these sewing machines for basic sewing arts and crafts sewing machine work.

How do you properly maintain a mechanical sewing machine for long-term durability?2

Answer: Clean your mechanical sewing machine after each sewing project. Oil sewing device parts regularly using sewing machine oil. Check sewing accessories and replace worn needles. Store the sewing equipment in a dry area. Regular maintenance keeps the sewing machine, bobbin, and sewing tools working well for home and garment sewing.

Which essential parts should you regularly check on a mechanical sewing machine?3

Answer: Check the needle, bobbin, and presser foot on your mechanical sewing machine. Inspect sewing device feed dogs and tension dials. Examine sewing machine accessories, such as the foot pedal and cords. Look for wear on sewing equipment and sewing tools. Maintain these sewing machines for reliable home and garment sewing.

How does the bobbin system work in a mechanical sewing machine?4

Answer: The bobbin in a mechanical sewing machine holds the lower thread. The sewing device combines the top and bobbin threads for each stitch. Feed dogs move fabric as the sewing machine forms stitches. Proper bobbin winding helps sewing equipment run smoothly. This system is key for garment sewing and home sewing arts.

What common issues cause tension problems in mechanical sewing machines?5

Answer: Dirty sewing machine parts cause tension issues in mechanical sewing machines. Incorrect threading of the sewing device leads to problems. Worn sewing accessories, like old needles or bobbins, affect stitches. Dust inside sewing equipment can cause uneven tension. Always check sewing tools and machine sewing paths for smooth operation.

What safety precautions should be followed when operating a mechanical sewing machine?6

Answer: Unplug the mechanical sewing machine before maintenance. Keep sewing device cords in good condition. Use proper sewing accessories and sewing tools only. Keep fingers away from the needle area. Store sewing equipment and sewing machines safely. Follow instructions for home sewing projects and mechanical fabric machine use.

How can you troubleshoot feed dog problems on a mechanical sewing machine?7

Answer: Clean the feed dogs on your mechanical sewing machine after every project. Check for fabric or thread jams in sewing device parts. Adjust the feed dog lever as needed. Replace worn sewing accessories. Test sewing equipment with scrap fabric. These sewing machines need free-moving feed dogs for garment sewing and crafts.

What accessories are most useful for mechanical sewing machine users?8

Answer: Extra bobbins, assorted needles, and presser feet help your mechanical sewing machine. Seam guides and thread cutters improve sewing device results. Storage boxes keep sewing accessories and sewing tools organized. Good sewing equipment supports every home sewing project. These accessories fit most sewing machines and sewing mechanical machines.

Last Updated on January 8, 2026 by msj484

DISCLAIMER (IMPORTANT): This information (including all text, images, audio, or other formats on FamilyHype.com) is not intended to be a substitute for informed professional advice, diagnosis, endorsement or treatment. You should not take any action or avoid taking action without consulting a qualified professional. Always seek the advice of your physician or other qualified health provider with any questions about medical conditions. Do not disregard professional medical advice or delay seeking advice or treatment because of something you have read here a FamilyHype.com.