RC rock climbers are taking the world of remote control cars to new heights, inviting climbing enthusiasts and the broader rc climbing community to conquer rugged trails and rocky terrain. Whether you’re a hobbyist looking to customize your crawler with advanced suspension and motor upgrades or a newcomer curious about the differences between indoor rock climbers and outdoor rock climbers, this comprehensive guide explores everything you need to know. Discover top brands, essential features, performance tips, and expert answers to common questions to help you master your next climb.

Featured Products

Best Overall • Best Value • Premium Option

Note: As an Amazon Associate I earn from qualifying purchases. Some of the links on this site are affiliate links — when you buy through those links, I may earn a small commission at no extra cost to you.

Understanding Suspension, Tires, and Drivetrain in RC Crawlers

Every rc rock climber relies on suspension, tires, and drivetrain for performance. These systems control grip, crawl speed, and climbing ability. Choosing the right combination helps climbing enthusiasts and the rc climbing community tackle tough terrain and rocks.

Soft tires give better grip on rough trails. Four-wheel drive increases power and traction for rock climbing. Adjustable suspension lets climbers rc tune their crawler for mud or steep terrain. Understanding these systems is essential before exploring key components affecting crawl and climb ability.

Key components affecting crawl and climb ability

- Tire compound and tread pattern impact traction for rc rock climbing over mud and rocks.

- Drivetrain gearing affects crawl rc speed and torque for steep climbs.

- Suspension travel lets rc climbers maintain tire contact on uneven terrain.

- Articulated steering helps rc rock climbers maneuver through tight obstacles and trail sections.

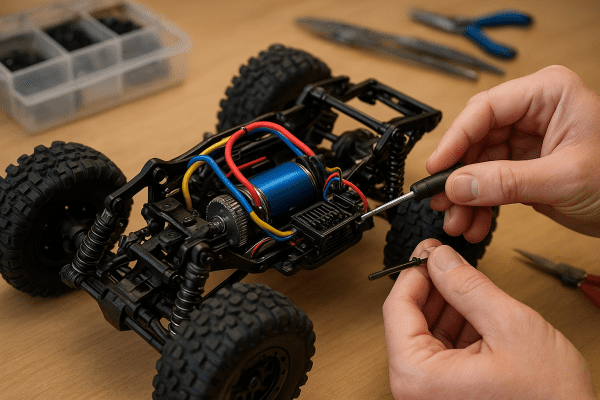

Enhancing Performance with Motors, Gears, and Electronics

Upgrading motors, gears, and electronics can transform rc rock climbers. These changes impact speed, torque, and precision. Many climbing enthusiasts and the rc climbing community want better throttle response. Electronics affect how the truck handles steep rock or mud trails.

Swapping in a brushless motor increases efficiency and power. Gear changes can boost climb rc torque or slow the vehicle for control. Upgraded electronics like waterproof ESCs improve reliability for outdoor rock climbers. Next, explore powertrain upgrades for increased torque and control.

Powertrain upgrades for increased torque and control

- Swapping to a lower pinion gear boosts crawl rc torque for rock climbing over steep obstacles.

- Installing metal driveshafts helps climber rc trucks handle high power loads on rough terrain.

- Upgrading to high-capacity lipo batteries increases runtime for outdoor rock climbers and trail adventures.

- Adding a programmable esc lets rc climbing enthusiasts fine-tune throttle curves for smoother control.

Comparing 4WD Systems, Axles, and Rock Terrain Adaptability

RC rock climbers use different 4WD systems and axle types to handle rough terrain. These setups impact traction, control, and how easily climbers rc navigate rocks. Suspension, drivetrain, and tires all work together for climbing performance.

Some rock climbers use portal axles for extra ground clearance. Others rely on straight axles for stability. Outdoor rock climbers prefer 4wd for grip on mud or steep trails. Drivetrain tuning helps the climbing community tackle unique obstacles. This leads into drive configurations and terrain response differences.

Drive configurations and terrain response differences

- Rock climbing rc trucks with 4ws steering handle tight switchbacks on rough trail terrain.

- Climb rc models using 6×6 drive configurations gain extra traction for mud and loose rock.

- Portal axles on climbers rc vehicles improve ground clearance for outdoor rock climbing.

- Drivetrain choices affect how climbing enthusiasts adjust speed and torque on technical obstacles.

Customizing Chassis, Wheels, and Scale Rock Crawler Features

Customizing rc rock climbers lets climbing enthusiasts shape their trucks for unique looks and trail needs. Changing wheels, chassis, or scale features helps climber rc models stand out. Many in the climbing community enjoy upgrades for both appearance and better rock climbing performance.

Swapping wheels or adding metal parts boosts durability and trail handling. Chassis upgrades improve articulation for tough rock terrain. Scale details like lights or bumpers create realistic rc climbing trucks. Costs for wheels or scale parts range from $15–$50 per unit. Next, learn about personalization options for appearance and functionality.

Personalization options for appearance and functionality

- Swap in LED light bars or rock lights to boost rc climbing visibility and scale appearance.

- Add custom paint or decals for unique climber rc truck style on any trail.

- Install metal bumpers or sliders for extra protection when tackling tough rock terrain.

- Fit weighted wheels or beadlock rims to enhance traction and climbing performance for rc rock climbers.

Battery Maintenance, Charging Safety, and Electronics Longevity

Proper battery maintenance is essential for all rc rock climbers. Safe charging protects your truck and electronics from damage. Good habits extend the life of your batteries and keep your climbing adventures safe and reliable.

Always use approved chargers for your lipo batteries. Store batteries in a cool, dry place and check for damage before use. Many climbing enthusiasts replace batteries every 12–18 months. Next, learn effective battery care routines for safe and extended use.

Battery care routines for safe and extended use

- Let rc rock climbers cool down batteries completely before each recharge to avoid overheating.

- Rotate multiple lipo packs during long climbing sessions to extend battery and electronics lifespan.

- Inspect battery wires and connectors on your climber rc for wear or damage after every trail run.

- Store rock climbing batteries at partial charge in a fireproof bag to protect your vehicle and electronics.

Troubleshooting Steering, Transmission, and Servo Power Issues

RC rock climbers sometimes face issues with steering, transmission, or servo power. These problems can limit climbing performance and handling. Fast diagnosis helps climbing enthusiasts keep their truck running smoothly. Most steering or drivetrain fixes are simple for patient climbers rc users.

Stiff steering, weak servo, or stuck transmission can frustrate the climbing community. Worn gears or low battery voltage cause common failures in rock climbing rc vehicles. Parts like servos cost around $12–$40 per unit. For practical solutions, see the upcoming Common problems and step-by-step diagnostic tips.

Common problems and step-by-step diagnostic tips

- Check for loose steering links or worn bushings if your rc climber has poor wheel alignment or response.

- Listen for clicking or skipping in the drivetrain when rock climbing to identify stripped gears or transmission issues.

- Test servo power by turning the wheels while the truck is stationary; weak movement often signals low battery voltage in your rc rock climbers.

- Inspect all wiring and connectors after muddy trail runs, as debris can disrupt electronics and cause steering or power loss in your climbing rc.

Waterproofing Electronics, Protecting Motors, and Care Tips

Protecting electronics and motors keeps rc rock climbers reliable in wet conditions. Water can damage your drivetrain, motor, and electronics. Indoor rock climbers worry less, but outdoor rock climbers need extra care. Good habits help climbing enthusiasts avoid costly repairs and extend vehicle life.

Use waterproof grease on gears and seal receiver boxes to block mud. Cover exposed wiring on your climber rc truck with liquid electrical tape. After muddy trails, clean and dry all electronics. Next, learn specific Methods for safeguarding electronics during wet conditions to keep your rock climbing rc running strong.

Methods for safeguarding electronics during wet conditions

- Elevate rc rock climbers’ receivers and electronics above the chassis to avoid direct water exposure on the trail.

- Use dielectric grease on battery and motor connectors to prevent corrosion in wet rock climbing environments.

- Fit waterproof servo cases on your climbing rc for reliable steering during mud and rain sessions.

- Seal drivetrain access points with silicone to keep moisture out of critical crawler components during outdoor rock climbing.

Improving Trail Handling with Upgrades and Weighted Wheels

Upgrading rc rock climbers with better wheels and suspension helps with rough trails. Weighted wheels add grip and stability for climbing enthusiasts. These changes let climbers rc handle sharp rocks and loose terrain. Trail performance and control improve for both indoor rock climbers and outdoor rock climbers.

Adding metal beadlock wheels or wheel weights costs around $15–$40 per set. Heavier wheels increase traction and help the truck stay upright. Swapping in stiffer suspension or tuning the shocks can also help climbing rc trucks. These changes set the stage for performance enhancements for stability and obstacle climbing.

Performance enhancements for stability and obstacle climbing

- Adjusting tire pressure on rc climbers improves grip and reduces rollovers on uneven rock.

- Fine-tuning suspension preload helps climbing enthusiasts maintain stability during steep rock climbing.

- Adding anti-roll bars to your rc rock climbers reduces chassis sway when tackling rough terrain.

- Upgrading to wider wheels increases contact area for better obstacle climbing in the climbing community.

Cleaning Mud, Dirt, and Debris from Crawler Components

Mud, dirt, and debris can quickly build up on rc rock climbers after each trail run. Cleaning these parts protects your truck, improves performance, and extends electronics life. Regular care is essential for climbing enthusiasts, outdoor rock climbers, and anyone in the climbing community.

Focus on suspension, drivetrain, and wheel areas, as these collect the most debris. Use soft brushes or compressed air for tight spaces on your rock climber. Simple cleaning tools cost around $8–$15 per set. Next, learn effective cleaning techniques for critical parts to keep your climbers rc ready for action.

Effective cleaning techniques for critical parts

- Use a soft detailing brush to remove mud from suspension and drivetrain areas on your rc climber.

- Rinse tires and wheels with low-pressure water to clear debris after intense rock climbing trails.

- Dry all electronics on your climbing rc truck with compressed air to prevent corrosion and protect battery connections.

- Inspect and clean axle housings regularly to keep your rock climbers performing smoothly on every terrain.

Long-Term Storage, Warranty, and Replacement Parts Solutions

Long-term storage keeps your rc rock climbers ready for every season. Warranty coverage protects against defects in electronics or drivetrain. Replacement parts let climbing enthusiasts and the climbing community repair or upgrade their trucks when needed. Proper care saves money and extends your crawler’s lifespan.

Always store batteries and electronics in a dry, cool place. Many climbers rc models offer replacement parts, with prices starting around $8–$25 per unit. Warranty terms for suspension or electronics typically last 90 days to one year. Next, explore Best practices for preserving and repairing your crawler.

Best practices for preserving and repairing your crawler

- Replace worn suspension or drivetrain parts on your rc climber promptly to maintain optimal trail performance.

- Keep spare tires, steering links, and electronics for quick repairs during climbing rc sessions.

- Periodically lubricate moving parts on your rock climbing truck to prevent rust and extend component life.

- Document all upgrades and maintenance for your climbers rc to track the longevity of key vehicle parts.

Final Thoughts:

RC rock climbers offer an exciting way for climbing enthusiasts and hobbyists to experience the thrill of tackling challenging terrain right from their backyard or local trail. Whether you’re customizing your truck with upgraded suspension or joining the growing climbing community, the right combination of drivetrain and electronics ensures peak performance and durability. Ready to take your passion for rock climbing rc to the next level? Explore top brands, compare features, and start building or upgrading your own climber rc for endless adventure and skill-building fun.

Frequently Asked Questions (FAQs)

What features make a good RC rock climber for tackling rough terrain?1

Answer: A good rc rock climber uses 4wd, soft tires, and high suspension. Climbing enthusiasts prefer adjustable drivetrain and metal parts. Strong steering improves rock climbing. Weighted wheels help grip mud and rocks. The climbing community values durable electronics and easy upgrades. Trail performance improves with these features for all climbers rc.

How do suspension and tire choices affect RC rock climber performance?2

Answer: Suspension and tire choices change rc rock climbers’ grip and control. Soft tires improve rock climbing traction. Adjustable suspension helps climbers rc handle rough terrain. Climbing rc trucks with good articulation keep wheels on rocks. The climbing community recommends tuning suspension for every trail. Better tires and shocks help all climbing enthusiasts.

What are the most common drivetrain configurations in RC rock climbers?3

Answer: Most rc rock climbers use 4wd drivetrain for best climbing. Climbing community trucks may have straight or portal axles. Some climbers rc use 6wd for extra traction. Drivetrain choice affects rock climbing speed and torque. Climbing enthusiasts pick configurations for trail, mud, or indoor rock climbers. All variations help tackle tough terrain.

How can you safely maintain and charge RC rock climber batteries?4

Answer: Always charge rc rock climbers’ batteries with approved chargers. Store lipo packs in a fireproof bag. Let batteries cool after rock climbing before recharging. Check connectors for damage after mud or trail runs. Climbing enthusiasts rotate multiple batteries for safety. Proper care extends battery and electronics life for all climbers rc.

What are effective ways to waterproof the electronics in RC rock climbers?5

Answer: Seal rc rock climbers’ electronics with waterproof grease and silicone. Use dielectric grease on connectors for mud runs. Elevate electronics above the chassis in climbing rc trucks. The climbing community wraps receivers and servos for rock climbing. Climbing enthusiasts dry electronics after wet trails. These tips protect power, steering, and drivetrain from water.

Which upgrades most improve stability and climbing ability in RC rock climbers?6

Answer: Weighted wheels and soft tires help rc rock climbers climb better. Upgraded suspension adds stability for rock climbing. Metal parts improve durability on rough trails. Climbing enthusiasts add 4ws steering for tight turns. The climbing community says these upgrades help all climbers rc. Trail performance improves for both indoor and outdoor rock climbers.

How do you troubleshoot steering or servo issues in an RC rock climber?7

Answer: Check all rc rock climbers’ steering links for looseness or wear. Test servo by turning wheels while stopped on trail. Inspect wires and connectors after mud runs. Replace weak servos to improve rock climbing. Climbing enthusiasts clean dirt from drivetrain. These steps help the climbing community fix most climbers rc steering problems.

What is the best method for cleaning mud and debris from RC rock climber components?8

Answer: Use a soft brush for rc rock climbers’ suspension and drivetrain. Rinse wheels with low-pressure water after rock climbing. Dry electronics with compressed air for safety. Climbing enthusiasts clean axle housings after every trail. The climbing community says regular cleaning keeps climbers rc running well. Quick cleaning extends truck, tire, and electronics life.

Last Updated on December 23, 2025 by msj484

DISCLAIMER (IMPORTANT): This information (including all text, images, audio, or other formats on FamilyHype.com) is not intended to be a substitute for informed professional advice, diagnosis, endorsement or treatment. You should not take any action or avoid taking action without consulting a qualified professional. Always seek the advice of your physician or other qualified health provider with any questions about medical conditions. Do not disregard professional medical advice or delay seeking advice or treatment because of something you have read here a FamilyHype.com.